You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knife sheaths

- Thread starter Frodo

- Start date

Help Support Homesteading & Country Living Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Sep 7, 2013

- Messages

- 18,315

I generally don't go too fancy. But for my friend's Bowie I felt an obligation to do it up right. Leather stitching is for show. The real stitching is Kevlar. I used the thickest cowhide I could find on the web. Besides the tie down strap, I later added a gunslinger style leather thong that loops over the small end of the coffin handle.

Here is the story behind the Bowie:

Back in the 1970's I was making knives. When Browning quit making the Sweet Sixteen, I immediately ran to the gunshop and put one on layaway because I didn't have enough cash to pay in full for it. I was slowly paying it off, but my friend said he would pay it off for me if I made him a Bowie.

He wanted a REAL Bowie, 18" long with brass backstrap on the blade and shaving sharp false edge.

Not long after that my knife making equipment was stolen. And I had a change in employment which kept me too busy to start over again with the knife making (which is VERY time consuming)

So the Bowie never got made...until...

After I retired, I decided to take up knifemaking again. And of course that obligation for my friend's Bowie weighed heavily on my mind, so that was my first knife.

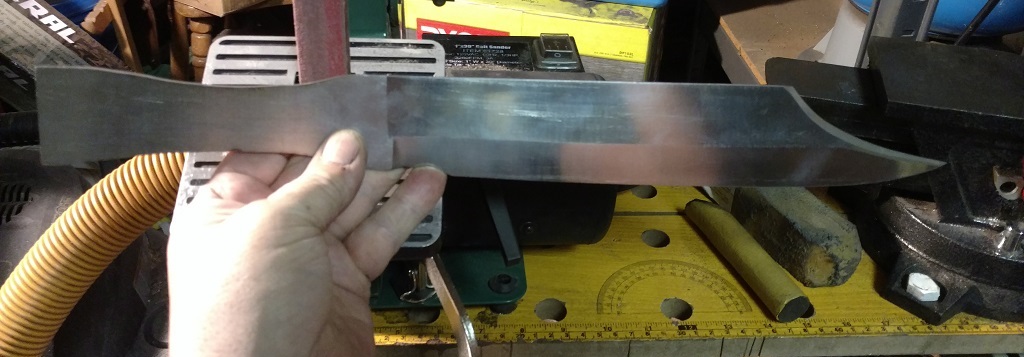

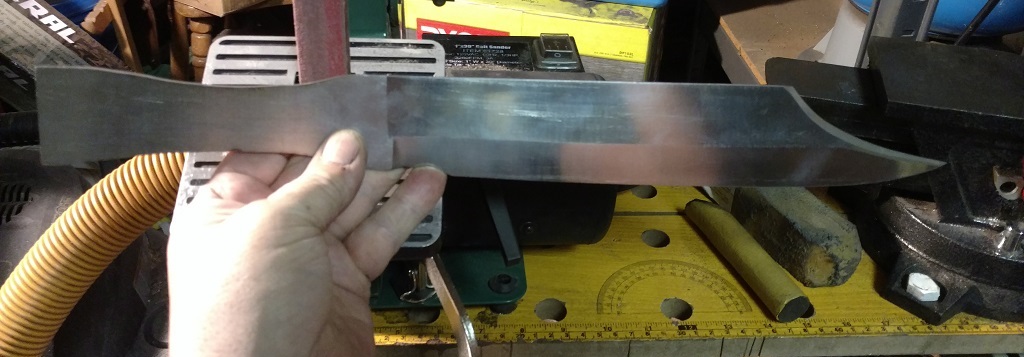

By then he was living in Oklahoma and I was living in Georgia. One day out of the blue he got an email with this picture:

He knew what it meant!

That knife took me FOREVER to make. D2 is notoriously difficult to work with on large blades. I don't know how many sanding belts I went through. I had to keep ordering premium belts online because the ones I could buy locally didn't last any time. So I can confidently say I AIN'T DOIN' THAT AGAIN!

I used up the rest of that bar of D2 and have been using easier steels to work with. And smaller knives.

Here is the story behind the Bowie:

Back in the 1970's I was making knives. When Browning quit making the Sweet Sixteen, I immediately ran to the gunshop and put one on layaway because I didn't have enough cash to pay in full for it. I was slowly paying it off, but my friend said he would pay it off for me if I made him a Bowie.

He wanted a REAL Bowie, 18" long with brass backstrap on the blade and shaving sharp false edge.

Not long after that my knife making equipment was stolen. And I had a change in employment which kept me too busy to start over again with the knife making (which is VERY time consuming)

So the Bowie never got made...until...

After I retired, I decided to take up knifemaking again. And of course that obligation for my friend's Bowie weighed heavily on my mind, so that was my first knife.

By then he was living in Oklahoma and I was living in Georgia. One day out of the blue he got an email with this picture:

He knew what it meant!

That knife took me FOREVER to make. D2 is notoriously difficult to work with on large blades. I don't know how many sanding belts I went through. I had to keep ordering premium belts online because the ones I could buy locally didn't last any time. So I can confidently say I AIN'T DOIN' THAT AGAIN!

I used up the rest of that bar of D2 and have been using easier steels to work with. And smaller knives.

Last edited:

Nice blade Dr,

Digging the brass accent

The Sheath?

It is a gift from the heart

And that is pretty damn special

Your Bud is a lucky guy

Digging the brass accent

The Sheath?

It is a gift from the heart

And that is pretty damn special

Your Bud is a lucky guy

- Joined

- Sep 7, 2013

- Messages

- 18,315

OH, and I printed up a frame-able "Certificate of Authenticity" for him.

- Joined

- Sep 7, 2013

- Messages

- 18,315

You know, I never really understood the coffin handle before making one. I always thought it was not ergonomic. Boy was I wrong!

- Joined

- Sep 7, 2013

- Messages

- 18,315

Yes.Does the sheath have a welt?

And the inside of the sheath has a hard finish to keep the VERY sharp blade from slicing it

Ok. Sorry did not see itYes.

I mess up all the time making a left handed sheath instead of right hand

Drives me nuts

- Joined

- Sep 7, 2013

- Messages

- 18,315

I told him not to run his finger on the edge. He won't be able to feel it when it slices his finger open.

Check this out Dr

This is hard to do but looks soooooobad ass

This is hard to do but looks soooooobad ass

Impressive work here- those look great.

Nice work all around guys! I miss it!

- Joined

- Dec 15, 2017

- Messages

- 1,607

This past weekend I had a gentleman approach me at our booth at the craft fair and wishes to for me collaborate with him in his knife making venture.

He showed me some pictures of is hand made knives, with only a shot of them on a phone they looked very well made, then he said here is my problem I have tried to make a high quality sheath to go with each knife.... After seeing a pic of his sheath I had to agree with him that his talents laid in the bladesmithing arena.

I told him that I did not run a production leather working outfit and a sheath would have to be custom fit and not cheap. He said he will give me a call to discuss details and he did not seem discouraged.

Just ask Frodo there is a lot of work when you use 10 and 12 oz leather! That stuff is stubborn.

I wish sometimes that the internet service here would allow me to post pictures ,but alas, y'all are spared, thank God for small mercies.

He showed me some pictures of is hand made knives, with only a shot of them on a phone they looked very well made, then he said here is my problem I have tried to make a high quality sheath to go with each knife.... After seeing a pic of his sheath I had to agree with him that his talents laid in the bladesmithing arena.

I told him that I did not run a production leather working outfit and a sheath would have to be custom fit and not cheap. He said he will give me a call to discuss details and he did not seem discouraged.

Just ask Frodo there is a lot of work when you use 10 and 12 oz leather! That stuff is stubborn.

I wish sometimes that the internet service here would allow me to post pictures ,but alas, y'all are spared, thank God for small mercies.

I do not get along with my knife makers .This past weekend I had a gentleman approach me at our booth at the craft fair and wishes to for me collaborate with him in his knife making venture.

He showed me some pictures of is hand made knives, with only a shot of them on a phone they looked very well made, then he said here is my problem I have tried to make a high quality sheath to go with each knife.... After seeing a pic of his sheath I had to agree with him that his talents laid in the bladesmithing arena.

I told him that I did not run a production leather working outfit and a sheath would have to be custom fit and not cheap. He said he will give me a call to discuss details and he did not seem discouraged.

Just ask Frodo there is a lot of work when you use 10 and 12 oz leather! That stuff is stubborn.

I wish sometimes that the internet service here would allow me to post pictures ,but alas, y'all are spared, thank God for small mercies.

They want a custom sheth but don't want to pay the $50 they want to give you 20 .that covers material I'm not doing this **** for free

Wow! That’s nuts. Especially if there is any sort of tooling involved. What is minimum wage there. It’s so annoying, but pointing out that that would just cover the cost of the materials and it takes about however long to make it, even at minimum wage which is what the kid pushing the broom at McDs makes, it would be $X amount.I do not get along with my knife makers .

They want a custom sheth but don't want to pay the $50 they want to give you 20 .that covers material I'm not doing this **** for free

- Joined

- Dec 15, 2017

- Messages

- 1,607

I agree totally frodo....I told him we would talk but I have seen leather knife sheath's that were made supposedly custom for a blade maker.

They were askin between $250 to $350 per unit, I found a blade I liked but the holder was OK so I ask what was the blade price sans sheath \ -$20!

So yep ,I suspect where this is going, just like you said.

They were askin between $250 to $350 per unit, I found a blade I liked but the holder was OK so I ask what was the blade price sans sheath \ -$20!

So yep ,I suspect where this is going, just like you said.

I had a knife maker actually get madI agree totally frodo....I told him we would talk but I have seen leather knife sheath's that were made supposedly custom for a blade maker.

They were askin between $250 to $350 per unit, I found a blade I liked but the holder was OK so I ask what was the blade price sans sheath \ -$20!

So yep ,I suspect where this is going, just like you said.

He wanted 5 sheaths usually they would be $50 each.because he wanted 5. I cut him a break at $40 each

He got huffy and wanted to pay $20 each

I told him to go to Temu they got fake stuff for $2.00

- Joined

- Dec 15, 2017

- Messages

- 1,607

Hey Frodo, I have been makin some knife sheaths (not for the bladesmith) hatchet and hawk head covers lately but I am havin a tough time keppin the bolsters sandwiched in position during the piercing process for stitching? The which hole process is difficult when using a stack of leather that may total to over 25oz or almost a half inch thick.

I am glueing the three sections together and even after extended drying gettin a straight punch thru not all at once and even using an extra long sharpened single nail to pierce I still get movement enuf to where I totally miss the opposite side stitch line... That wrankles me since my style is close to an even fitted symmetry look. Must be some latent OCD or the engineer commin out. Usually I find that when I hit a problem like this someone will point out a simple solution and I realize I've been overthinkin again.

I am glueing the three sections together and even after extended drying gettin a straight punch thru not all at once and even using an extra long sharpened single nail to pierce I still get movement enuf to where I totally miss the opposite side stitch line... That wrankles me since my style is close to an even fitted symmetry look. Must be some latent OCD or the engineer commin out. Usually I find that when I hit a problem like this someone will point out a simple solution and I realize I've been overthinkin again.

Cut out all your piecesHey Frodo, I have been makin some knife sheaths (not for the bladesmith) hatchet and hawk head covers lately but I am havin a tough time keppin the bolsters sandwiched in position during the piercing process for stitching? The which hole process is difficult when using a stack of leather that may total to over 25oz or almost a half inch thick.

I am glueing the three sections together and even after extended drying gettin a straight punch thru not all at once and even using an extra long sharpened single nail to pierce I still get movement enuf to where I totally miss the opposite side stitch line... That wrankles me since my style is close to an even fitted symmetry look. Must be some latent OCD or the engineer commin out. Usually I find that when I hit a problem like this someone will point out a simple solution and I realize I've been overthinkin again.

Sand and shape as desired

Stack your pieces. Make a mark on both top and bottom pieces. Where the end of the welt is

Use your compass to make a stitch line on each piece

Go a l to the mark you made, from that mark. Use your chisels to make holes in each piece, using your mark as the starting poiint

Hounowhave holes in all pieces that if done correctly will line up

Glue all together. Use old needles as line up tools

- Joined

- Dec 15, 2017

- Messages

- 1,607

Thanks feller I have a person wanting a custom sheath to be made in a cupla weeks I'll tryit then.

Special sheath. Here is one that makes a statementThanks feller I have a person wanting a custom sheath to be made in a cupla weeks I'll tryit then.

You know how to make a simple fold over knife sheath right?

Make your fold over , then draw out your design of whatever overlay you want I like a diamond shape. Which this is not

Cut your leather every 1/4" or whatever you feel is right

At this point I use a small punch at the corner of the cut, but you be you

Then. Cut 1/4" strips. Turn the strips so the flesh side is opposite of the sheath. This in my opinion brings out a contrast but again, Do it your way each strand as you start, and the finish. No need to glue the center.

When done. Sew the edges and your welt with your machine

After it is sewn Use an antique gel applied with cotton ball.

This sucker will scream Special.

- Joined

- Dec 15, 2017

- Messages

- 1,607

Thanks Frodo, gonna hafta think on that one

I can copy that pattern easy

I can copy that pattern easy

It is easy. And looks good. I have a couple Gimmie a day or so and I can show you finished dealThanks Frodo, gonna hafta think on that one

I can copy that pattern easy

You need to to stop farting around and either use your machine or sell it

Opps. My bad. That's an opinion.

You don't need to do either. Over stepped my boundary

- Joined

- Dec 15, 2017

- Messages

- 1,607

Too late the wife has claimed it now......

lol. I know that feelingToo late the wife has claimed it now......

For every 4 bags I make my wife grabs one of them. They disappear into her she cave never to be seen again

- Joined

- Dec 15, 2017

- Messages

- 1,607

Yep, purse locks,ChapStick holders,wallets, belts, rfid cards sumwhere around here is a stash of inventory!!!