- Joined

- Apr 4, 2020

- Messages

- 7,461

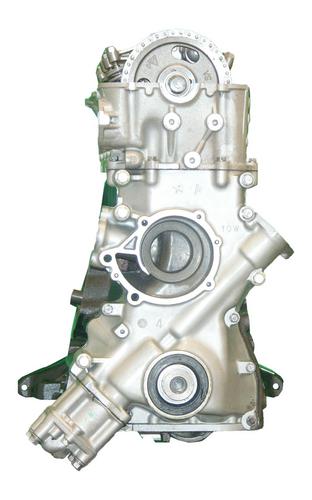

Edit: the following assumes that the front cover, or oil pump, have not been removed and reinstalled.

@Mr.Meer: The first order of business is to verify 0 degrees top dead center on cylinder #1.

Using a long screwdriver thru the sparkplug hole, you can feel the #1 piston come up to the top as you rotate the crank clockwise with a wrench.

When it is all the way at the very top, the mark on the front pulley should align with the 0 on the timing scale.

If there is no mark on the pulley, we will have to make one.

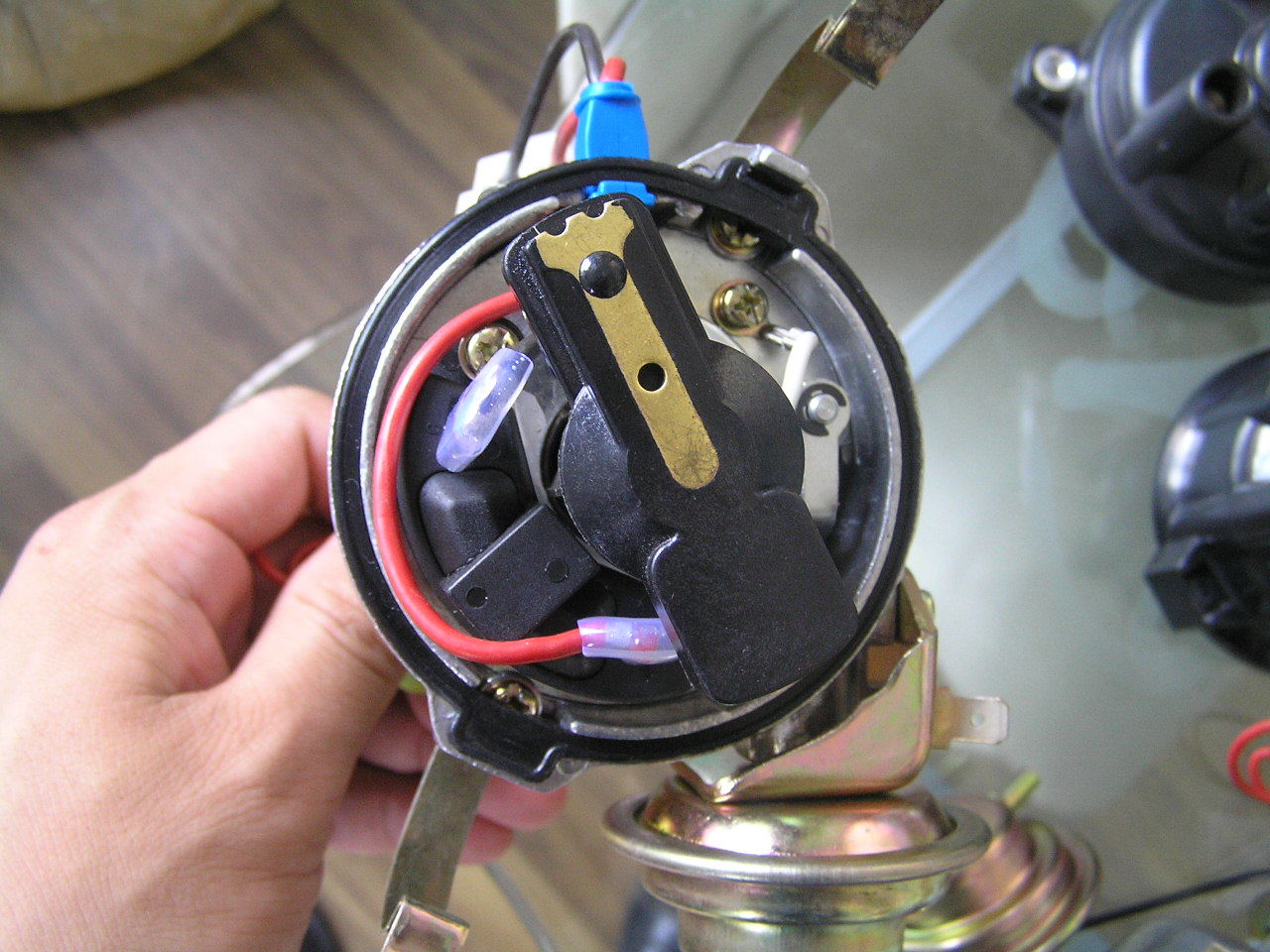

Next we will rotate the crank clockwise until the distributor rotor is pointing at the #4 sparkplug wire terminal in the distributor cap.

If the cam is in the right time, the exhaust valve will on #1 will just finish closing (moving upward) as we rotate the mark on the pulley up to the 0 on the timing scale. Immediately the intake valve will begin to open if we keep turning the crank past 0.

This period at the end of the exhaust stroke and the beginning of intake is called "overlap".

If the cam chain is even one tooth off, one of the valves will be moving when it passes 0.

When you get the cam in time, don't try to start it until you adjust the valves.

When a head comes back from from being worked the valves are always too tight (meaning they can't close completely)

We'll adjust the valves in the next post.

Will try this first.

Back in a little while.

I knew he was ok it didn't hit him that hard but it made a funny sound.

I knew he was ok it didn't hit him that hard but it made a funny sound.

Or the Mayflower, the other useless money pit.

Or the Mayflower, the other useless money pit.